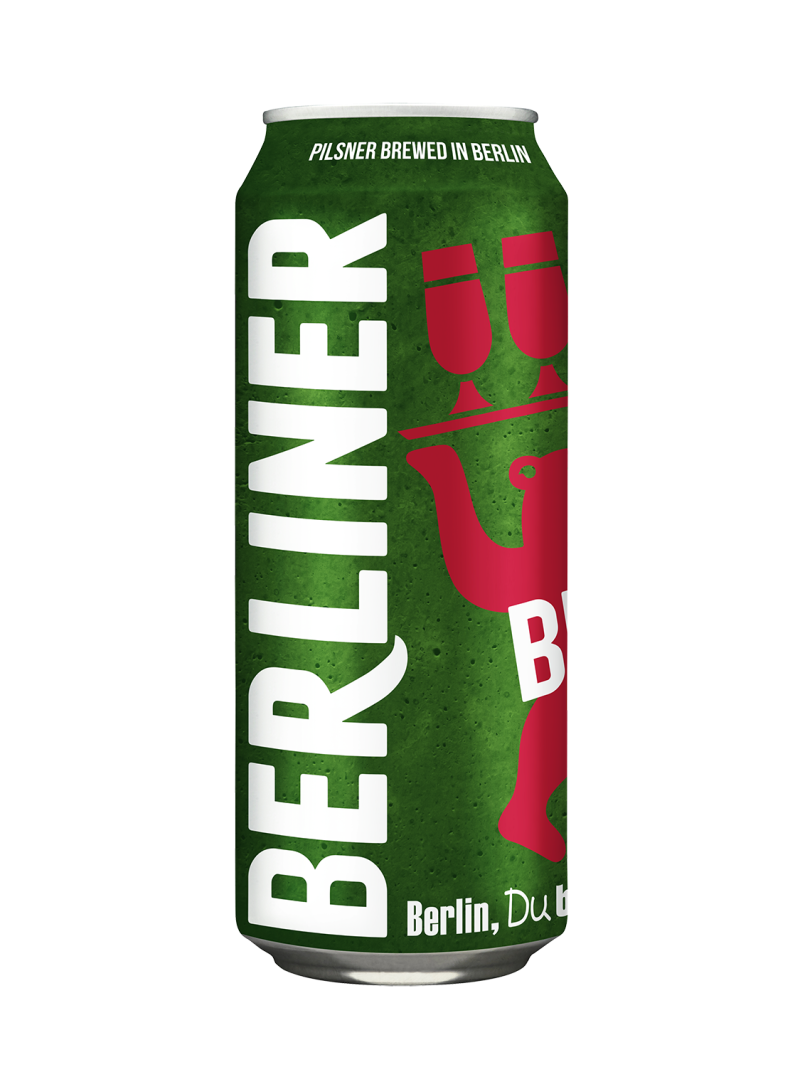

BERLINER PILSNER, FUEL FOR ALL THOSE, WHO ARE THRILLED BY THE VIBRANT VIBES OF BERLIN.

Water, barley, malt and hop – you do not need more to brew a good Pils. Serendipity for the best ingredients from our nature, craftsmanship und great know-how. But first of all passion for really good beer - Berliner Pilsner. The original just with the red bear.

Type: Pilsner

Brewing process: bottom-fermented

ABV: 5,0% alc./vol.

| Calories | 163 kJ (40 kcal) |

| Total Fat | <0,5 g |

| - Saturated Fat | <0,1 g |

| Total Carbohydrate | 2,2 g |

| - Sugar | <0,5 g |

| Protein | <0,5 g |

| Salt | <0,01 g |